Table of Contents

Key Takeaways

✔ There are 10 main types of warehouses, each serving a distinct role.

✔ Choosing the right warehouse impacts cost, efficiency, and scalability.

✔ Automation and AI are reshaping how modern warehouses operate.

✔ Specialized warehouses like bonded and cold storage ensure regulatory compliance.

✔ Partnering with experts like 3PL Warehouse By Best simplifies logistics management and boosts reliability.

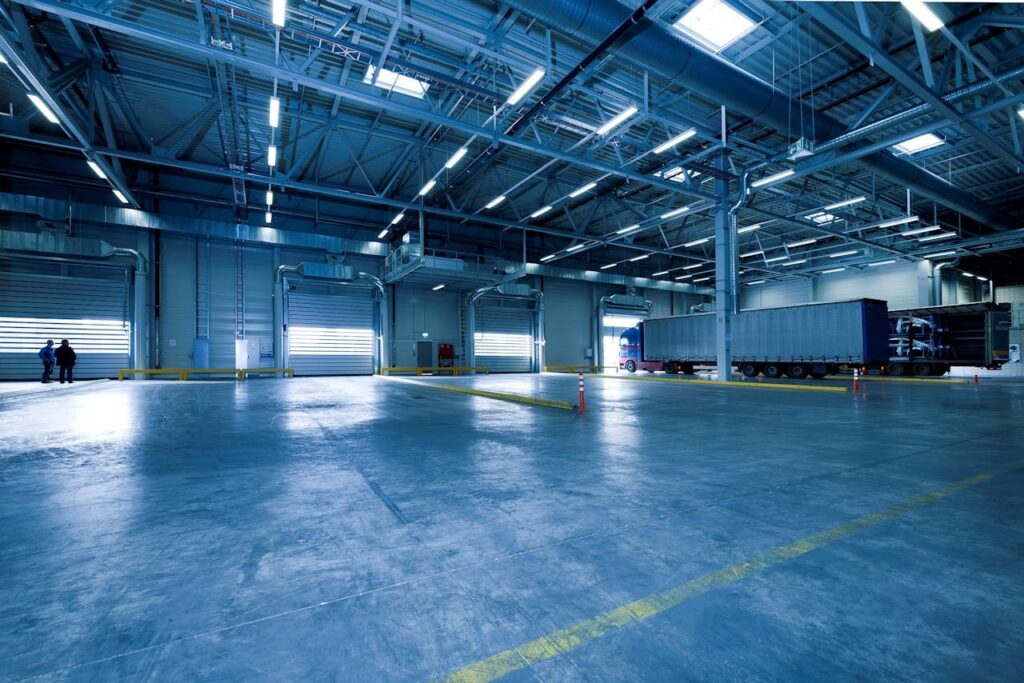

In logistics, warehouses are the beating heart of the supply chain. Whether you’re managing inventory for an eCommerce store, storing raw materials, or handling international shipments, choosing the right warehouse type can determine how efficiently your operations run. From traditional storage spaces to tech-powered fulfillment centers, each warehouse serves a unique purpose.

This guide from 3PL Warehouse By Best breaks down the 10 common types of warehouses and how they drive smarter, faster, and more cost-effective logistics.

What are the Main Types of Warehouses?

Warehouses are specialized facilities designed to store, manage, and distribute goods. Each type caters to specific needs, industries, and business sizes. Understanding the different warehouse types helps companies align storage strategies with operational goals.

1. Public Warehouse

Public warehouses are open to multiple businesses, providing flexible and affordable storage options. They’re ideal for startups, small businesses, or those with seasonal inventory spikes. Their short-term contracts make them cost-effective without long-term commitments.

2. Private Warehouse

Owned and operated by a company for its exclusive use, private warehouses offer complete control over operations. They require more capital but deliver consistent branding, quality control, and long-term savings for large manufacturers and retailers.

3. Bonded Warehouse

Bonded warehouses store imported goods until customs duties are paid. These government-licensed facilities allow companies to delay tax payments, making them ideal for international trade and import-export businesses.

4. Smart Warehouse

A smart warehouse integrates automation, robotics, and AI to optimize inventory management and order processing. 3PL Warehouse By Best utilizes intelligent systems to reduce human error, improve speed, and enhance visibility across the supply chain.

5. Distribution Center

Distribution centers act as high-speed transfer hubs, focusing on product movement rather than long-term storage. They’re critical for eCommerce and retail, ensuring rapid order fulfillment and just-in-time deliveries.

6. Cooperative Warehouse

Owned by groups such as farmers or associations, cooperative warehouses reduce costs through shared resources. Members benefit from lower rates, better equipment, and collective bargaining power.

7. Cold Storage Warehouse

Cold storage warehouses are temperature-controlled environments built for perishable goods such as food, pharmaceuticals, and chemicals. They maintain strict temperature and humidity standards to preserve product integrity.

8. Fulfillment Center

Fulfillment centers specialize in processing online orders, from storage and picking to packing and shipping. They’re the backbone of eCommerce and help businesses scale without investing in their own logistics infrastructure.

9. Consolidated Warehouse

Consolidated warehouses combine small shipments from multiple suppliers into larger, more efficient loads. This reduces transportation costs and improves distribution efficiency for small to mid-sized businesses.

10. Cross-Docking Warehouse

Cross-docking minimizes or eliminates storage time by transferring goods directly from inbound to outbound transport. It’s ideal for fast-moving or time-sensitive products that need to reach customers quickly.

Quick Facts: Warehousing at a Glance

- Over 90% of U.S. warehouses are under 50,000 square feet.

- Smart warehouses can improve picking efficiency by up to 25%.

- Cold storage demand has risen 40% in the last five years.

- Cross-docking can reduce logistics costs by 20%.

- Distribution centers typically operate 24/7 to meet demand.

How Many Main Types of Warehouses are There?

10 main types of warehouses dominate the logistics industry. Each type fulfills a distinct role—from temperature-controlled storage to AI-driven automation—allowing businesses to select the right model for their products, budget, and operational needs.

What are the 5 Warehouse Processes?

Every warehouse, regardless of type, relies on five core processes that define its efficiency. Understanding these steps ensures smooth, consistent operations across all types of warehousing.

1. Receiving

Goods are inspected, verified, and logged into inventory systems upon arrival.

2. Putaway

Items are stored in designated areas for easy access and optimal space usage.

3. Picking

Warehouse staff or automated systems locate and retrieve items for order fulfillment.

4. Packing

Products are securely packed using protective materials and correct labeling.

5. Shipping

Orders are dispatched via the most efficient routes, ensuring on-time delivery.

What are Warehouses Used For?

Warehouses serve as the operational backbone for any business dealing with physical goods. Their uses extend well beyond simple storage.

Supporting Supply Chain Operations

They facilitate the smooth flow of goods between manufacturers, suppliers, and customers, helping businesses meet demand seamlessly.

Enhancing Inventory Control

Modern warehouse management systems provide real-time visibility, minimizing stockouts and overstocking.

Meeting Customer Expectations

By optimizing order fulfillment, warehouses enable faster delivery, improving customer satisfaction and retention.

3 Benefits of Choosing the Right Type of Warehouse

Selecting the appropriate warehouse type ensures your business remains competitive and adaptable to changing demands.

1. Cost Efficiency and Flexibility

The right setup prevents excess costs from underutilized space and offers scalability during seasonal peaks.

2. Improved Logistics and Delivery Speed

Strategically located warehouses minimize delivery times and shipping costs.

3. Industry-Specific Optimization

From bonded warehouses for imports to cold storage for perishables, matching your warehouse to your industry is key to compliance and performance.

How 3PL Warehouse By Best Streamlines Modern Warehousing

3PL Warehouse By Best combines advanced technology with tailored 3PL logistics solutions to help businesses scale efficiently. From smart warehouse systems and climate-controlled storage to nationwide distribution and real-time tracking, the company ensures precision, transparency, and reliability across all supply chain operations.

Frequently Asked Questions | About Types of Warehouses (FAQs)

What is the difference between a warehouse and a distribution center?

A warehouse stores goods for extended periods, while a distribution center focuses on processing and delivering orders quickly.

Which type of warehouse is best for small businesses?

Public or cooperative warehouses are affordable, flexible options that suit smaller operations and seasonal inventory needs.

How do smart warehouses improve efficiency?

Smart warehouses use automation and AI to streamline picking, packing, and shipping, reducing human error and operational costs.

What is an example of specialized warehousing?

Cold storage and bonded warehouses are specialized for temperature-sensitive goods and imported products, respectively.

What role does technology play in modern warehousing?

Technology drives automation, real-time tracking, and data analytics—key features that companies like 3PL Warehouse By Best leverage to optimize performance.

Choose the Right Warehouse Type for Your Business Success

Your warehouse is more than storage—it’s a strategic asset. The right facility can reduce costs, speed up fulfillment, and enhance customer satisfaction. Whether you need advanced automation or temperature-controlled storage, 3PL Warehouse By Best provides tailored solutions that move your business forward with precision and care. Contact the team today to find your perfect warehousing fit.